32/34, Jintan Udhyognagar, Behind Gas godown, Surendranagar – 363 002, Gujarat, INDIA.

Surface Finish

in Machining:

A Complete Guide

Introduction:

Machining Surface finish refers to the texture of a manufactured part, defined by roughness, waviness, and lay. It impacts durability, functionality, aesthetics, corrosion resistance, and lifespan of a product. Common finishes used are rough casting, turning, fine grinding, and polishing.

Surface finish in machining is an important aspect of manufacturing that affects the performance, aesthetic appeal, and durability. You should understand the nuances of surface finish that result in improved product quality and reduce production costs. In this blog, we tell you about the surface finish in machining, its importance, benefits, measurement methods, and practices in manufacturing.

In machining, Ra surface finish (arithmetic average roughness) is commonly used surface quality metrics. Ra quantifies the average vertical deviations of the surface profile from the mean line. It is expressed in micrometres (µm) or microinches (µin).

Here we also delve into the significance of ra surface finish, role of cutting tools and impact of machining. It also tells you about advanced finishing techniques and the latest technologies that affect surface quality.

What is Surface Finish in Machining?

The machining surface finish refers to the texture of the surface created during the manufacturing process. It consists of the three primary components, including waviness, roughness, and lay. These elements define surface texture and affect the performance of machined parts.

Types of Surface Finish

After knowing what is surface finish, you should look at its types. The different machining processes yield several surface finishes, each with their own characteristics and applications. You should understand the types of surface finishes to select the right process for your specific needs.

- Rough machining finish: This surface finish type is produced by fast cutting, and acceptable for internal features or non-critical surfaces.

- Fine machining finish: Fine Machining finish is achieved with optimized cutting parameters, and used where moderate precision is required.

- Ground finish: Ground surface finish is obtained with grinding operations, and gives better smoothness and tighter tolerances.

- Polished/mirror finish: Polished finish is achieved through polishing or lapping and crucial for medical implants, optics, or sealing components.

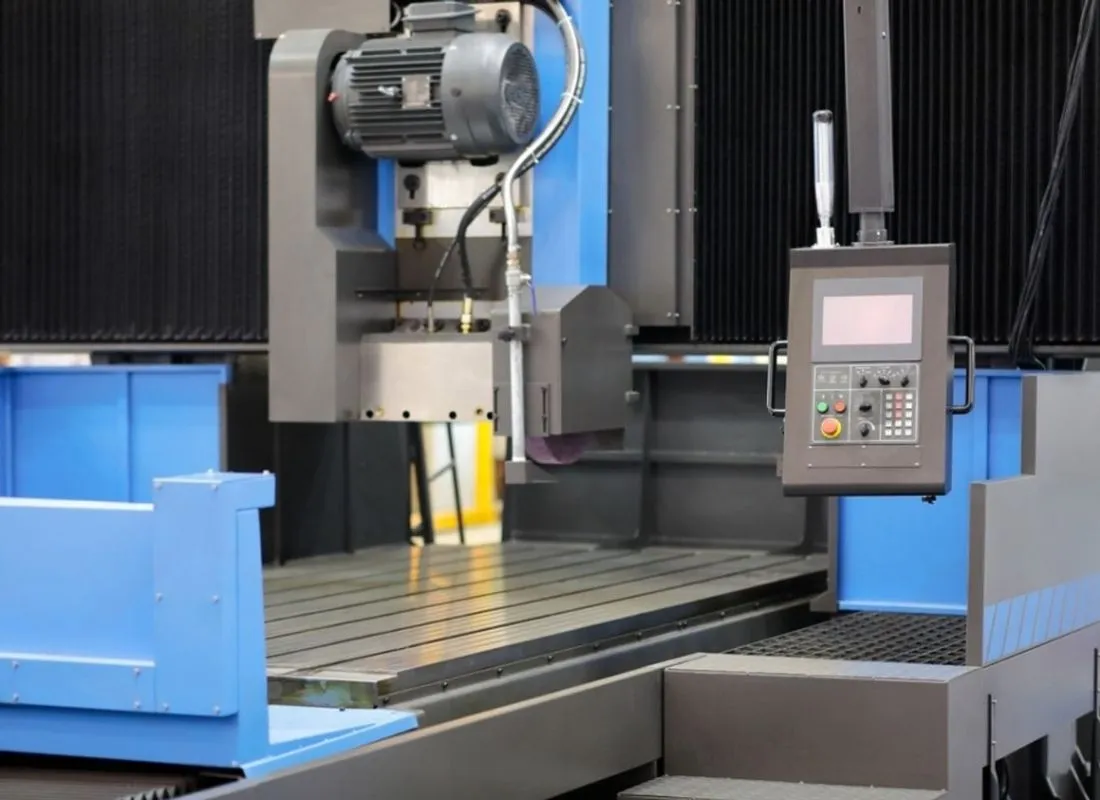

PinnacleGrinder manufactures ultra-modern surface grinding machines using state-of-the-art safety features and technologies to ensure superior performance and extensive protection.

Importance of Surface Finish in Machining

Here are the factors that show the importance of surface finish in machining, affecting functionality, enhancing durability, and machine aesthetics.

Impact on Functionality, Including Friction and Wear Resistance

A high-quality machining surface finish reduces friction between moving parts, which minimizes wear and extends the lifespan of components. For example, smoother surfaces in bearings and gears improve efficiency by decreasing heat generation. Compact surfaces also resist abrasive forces, which boosts durability and wear resistance.

Role in Durability, Corrosion Resistance, and Product Lifespan

Surface finish in machining impacts durability and corrosion resistance. A smoother surface acts as a barrier against environmental factors like moisture and chemicals, which helps prevent corrosion. Proper finishing methods, like polishing or coating, further increase a product’s lifespan by offering protection against wear and abrasion.

Aesthetic and Consumer-Facing Considerations

In products meant for consumers, ra surface finish impacts both functionality and visual appeal. For example, polished surfaces on electronic devices create a premium look, while textured finishes provide better grip and usability. Manufacturers often adjust surface finishes to match the product’s intended use and improve user experience.

What is Surface Finish in Machining?

A good surface finish in machining provides several advantages, as follows as:

- Improved functionality: A smooth ra surface finish lowers friction and wear, enhancing the part’s functionality and longevity.

- Better aesthetics: A smooth and polished surface finish boosts the part’s appearance, making it more attractive.

- Corrosion resistance: A good surface finish guards against corrosion by preventing moisture and other contaminants from entering the surface.

- Reduced manufacturing costs: A good machining surface finish lowers the need for further processing, cutting manufacturing costs.

5 Factors Affecting Surface Finish

When the surfaces of two objects touch, the quality of their finishes significantly affects their performance and durability. Here are some factors that impact surface finish:

Temperature

Temperature affects the volume of materials. As the temperature rises, metals expand, while polymers can get distorted. Consequently, the temperature during cutting can impact the surface finish of a component. High temperatures often lead to uneven surfaces and increased roughness, especially with mechanical methods.

Cutting Techniques

Traditionally, metal blades were used in cutting tools and machines. However, lasers and high-pressure water have become popular alternatives to traditional cutting methods. Overall, these new technologies provide better results, including smoother surface finishes. Laser cutting offers advantages over conventional methods, such as more precision and reduced roughness. A water jet cutter provides higher performance in finishing small parts.

Rate of Material Removal and Feed

The material removal rate (MRR) indicates how much material is taken away per unit of time. It shows the time needed to remove a specific amount from a workpiece. Feed refers to the distance the tool moves along or into the workpiece for each point passed in a unit of time. Both aspects impact surface finish quality.

Cutting Instruments

The surface finish in machining is defined by how and what machinery is used for cutting. The cutting speed, feed, and depth can all be adjusted on cutting machines. These variables are modified based on the type of material and the size of the component to avoid an overly rough surface.

Cutting Depth and Cutting Rate

Cutting depth refers to how deep the tool's cutting edge penetrates the workpiece material per pass. Cutting rate describes how fast a tool's cutting edge moves across the workpiece's surface over a given time. If the cutting speed is too high, the tool may dull due to excess heat if cutting speed is maintained too long, machining time increases, which reduces productivity.

How does Machining Surface Finish Impact Functionality and Lifespan?

Surface finish in machining plays a crucial role in the functionality and lifespan of manufactured parts. When you understand how surface finish levels connect with these factors, you can make better decisions for your projects.

- Reduced friction and wear: Smoother surface finishes usually mean less friction between moving parts, which extends their lifespan. This is especially important for components like bearings and pistons.

- Enhanced aesthetics: The machining surface finish creates a more appealing look for consumer products and machines. It also affects the market success by enhancing machining aesthetics.

- Improved corrosion resistance: Certain finishes, especially those achieved through chemical treatments, can enhance a part’s resistance to corrosion, extending its service life.

- Increased fatigue strength: Rough surfaces can concentrate stress, leading to early failures under cyclic loading. Finer finishes distribute stress evenly, boosting fatigue strength.

- Optimized sealing capabilities: In applications like gaskets and O-rings, surface finish is essential to ensure proper sealing, preventing leaks and potential failures.

- Enhanced heat transfer: In systems like heat exchangers, a specific surface finish can improve heat transfer efficiency, affecting overall system performance.

Empower Your Production with Pinnacle

Choosing Pinnacle means working with a team dedicated to your long-term success. Our integrated solutions improve your production capabilities, helping you enhance quality, lower costs, and increase productivity.

Simplify your polishing operations and achieve flawless finishes that exceed customer expectations. We offer not just surface grinding machines but a partnership grounded in a deep understanding of manufacturing processes and a commitment to innovation.

Conclusion

Surface finish in machining is essential to design and performance, boosting durability, functionality, and aesthetics. Picking the right finish means balancing material compatibility, application needs, and cost-efficiency.

From simple "as machined" finishes to anodizing's protective benefits, understanding your options leads to optimal results. The right surface finish is not just a detail; it is crucial for high-quality manufacturing.

Read related: A Complete Guide to Surface Grinding Techniques